Prototyping and Pre-Production Cable Assembly

Accelerate Product Development with Cablepoint’s Cable Assembly

We understand the critical role prototyping plays in bringing your product vision to life. Our prototyping service is designed to support your development process by providing high-quality, pre-production cables that meet your exact specifications.

From Concept to Production with Pre-production Cable Assemblies

Our prototyping capabilities enable you to:

Validate Your Designs: Test and refine your cable designs before committing to full-scale production.

Accelerate Time-to-Market: Quickly produce initial cable samples for testing and evaluation.

Ensure Accuracy: Verify cable assembly performance and compatibility with your system.

Mitigate Risks: Identify and address potential issues early in the development process.

Our Cable Prototyping Process

- Consultation: We work closely with you to understand your requirements and provide expert guidance.

- Rapid Prototyping: We utilise our advanced manufacturing and automation capabilities to create initial cable samples.

- Testing and Refinement: We conduct thorough testing and provide feedback to optimise performance.

- Pre-Production: We transition seamlessly to full-scale production once designs are finalised.

Benefits of Our Cable Assembly Prototyping Service

- Speed: Rapid turnaround times to meet your project deadlines.

- Flexibility: Customisation options to match your specific needs.

- Quality: Precision engineering and rigorous quality control.

- Expertise: Our experienced team provides technical support and guidance.

- Seamless Transition: Smooth transition from prototyping to full production.

By partnering with Cablepoint for your prototyping needs, you can accelerate your product development process, reduce risks, and achieve optimal results. Read about how we ensure quality at every stage of our process here.

How To Decide On Your Cable Assembly Company?

Experience

Established for over 30 years, Cablepoint brings a wealth of industry knowledge to every project. Our experts have tackled diverse specifications across various sectors, including military, electric vehicle and agricultural to name just a few, ensuring that you benefit from our deep pool of experience, from our friendly team. Our longevity is a testament to our consistent delivery of high-quality solutions and our ability to adapt to changing industry needs.

Sustainability

We’re committed to environmentally responsible practices, using eco-friendly materials and processes wherever possible. Our sustainable approach ensures that your cables align with global environmental goals.

Timely Delivery

Established for over 30 years, Cablepoint brings a wealth of industry knowledge to every project. Our seasoned experts have tackled diverse challenges across various sectors, ensuring that you benefit from our deep pool of experience. Our longevity is a testament to our consistent delivery of high-quality solutions and our ability to adapt to changing industry needs.

Global Reach

While proudly based in Hull in UK, our services extend worldwide. We have the capability to deliver our products across the globe, ensuring that no matter where you are, you can benefit from Cablepoint’s expertise.

Have any other questions? Check our frequently asked questions page.

Looking for a proactive manufacturing partner that delivers exceptional value?

Contact us today to discuss your cable assembly requirements

Cablepoint is your reliable choice. We’re committed to meeting both urgent and long-term requirements with precision and complete flexibility.

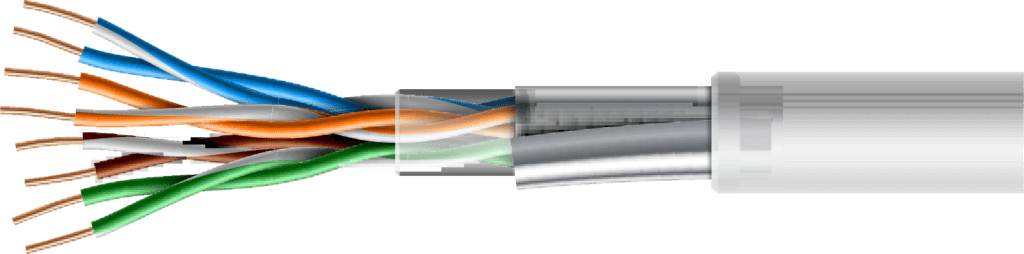

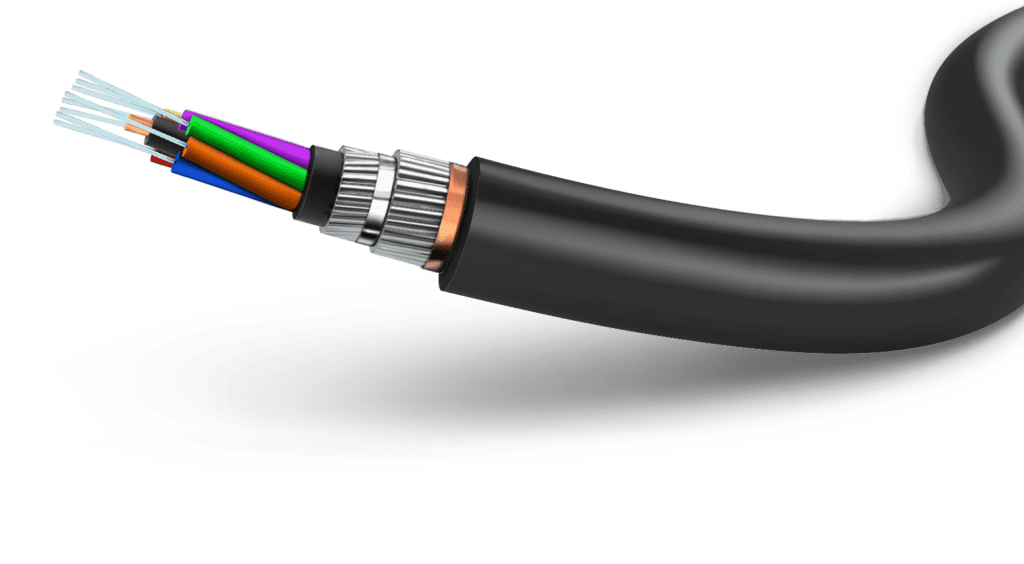

Our Production Capabilities

From simple wiring looms to complex harnesses, we can produce any required quantity. We also offer a refurbishment option on products, if required.

We produce a wide range of box build and control panels for a number of industries - from pharmaceutical to boiler manufacturers.

We have custom overmould and potting facilities on site. Depending on the cables required, the cost of any tooling can be amortised across your contract.

Our team is IPC trained, with experience producing a wide range of cable assemblies. From simple stripped, tinned, bootlaced and crimped wires to soldered wires and PCB connection.

We provide initial, pre-production cables to ensure complete accuracy, followed by full batch production. Customers may also use this facility for engineering prototypes and design ‘first-offs’.

We have two automated terminating machines with a tinning facility, enabling quality crimped wires to be produced economically and efficiently in large volumes.

Our clean room facility facilitates the production of high end F.O.D (Foreign Object Debris) sensitive specialist cables.