Cable and Wire Crimping

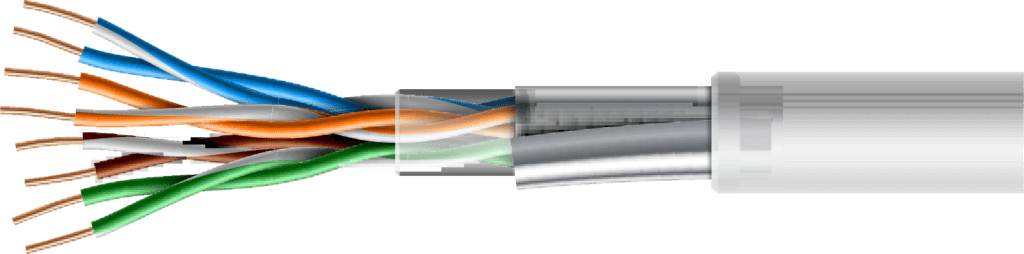

Crimped Wire Manufacturing: Custom Cable Crimping

We offer high-quality crimped wire produced through our automated terminating machines. Our state-of-the-art equipment, combined with our tinning facility, ensures the efficient and economical production of large volumes of crimped wires.

End to End Crimped Wire and Cable Assembly

Our process guarantees consistent and reliable crimping, meeting the highest industry standards. We have the capability to crimp a wide range of wire gauges and terminal types, providing flexibility to meet your specific requirements.

Looking for full-service cable assembly? Find out more about our full list of capabilities here.

UK-Based Crimped Wire and Cable Manufacturers

Our automated terminating machines with tinning facilities enable us to produce crimped wires in high volumes efficiently, resulting in cost-effective solutions for your projects. By streamlining the production process, we can offer competitive pricing without compromising quality.

Find out more about our dedicated equipment and workshops here.

Precision Crimped Cable and Connector Assembly

Crimped wires are essential components in various industries, including:

- Automotive

- Electronics

- Industrial automation

- Telecommunications

- Medical devices and manufacturing

Whether you need a small quantity for prototyping or large volumes for mass production, Cablepoint can meet your requirements. Request a call back here to discuss your project today.

Why Choose Cablepoint for Crimped Wire?

Decades of Experience:

Established for over 30 years, Cablepoint brings a wealth of industry knowledge to every project. Our experts have tackled diverse challenges across various sectors, ensuring that you benefit from our deep pool of experience. Our longevity is a testament to our consistent delivery of high-quality solutions and our ability to adapt to changing industry needs. Read more about Cablepoint and our aims here.

Sustainability

We’re committed to environmentally responsible practices, using eco-friendly materials and processes wherever possible. Our sustainable approach ensures that your wires and cables align with global environmental goals.

Timely Delivery

We understand the importance of deadlines and strive to deliver your solutions on time, every time. Have a specific deadline or project in mind? Get in touch to see how we can help.

Global Reach

While proudly based in the UK, our services extend worldwide. We have the capability to deliver our products across the globe, ensuring that no matter where you are, you can benefit from Cablepoint’s expertise.

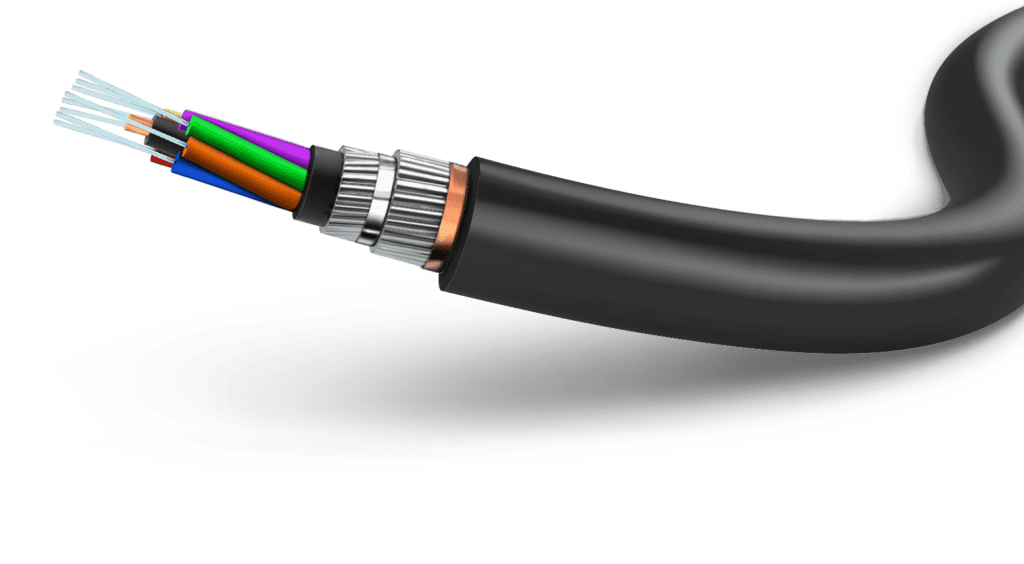

Common Questions About Moulded Cables

Moulded cables offer several advantages over traditional cable assemblies. They provide enhanced durability, protection against environmental factors (such as water, chemicals, and abrasion), and improved strain relief. The seamless integration of the cable and connector also eliminates potential points of failure.

The choice of material for moulded cable overmoulding depends on the specific application requirements. Common materials include:

- Thermoplastic elastomers (TPE): Offer flexibility, durability, and resistance to environmental factors.

- Thermoplastic polyurethane (TPU): Known for its toughness, abrasion resistance, and flexibility.

- Silicone: Provides excellent heat resistance, electrical insulation, and durability.

- Epoxy resins: Offer superior chemical resistance and mechanical properties.

Yes, Cablepoint can mould different cable types to suit various applications. Whether you need power, data, or signal cables, we can create custom moulded cable assemblies.

The lead time for a moulded cable project varies depending on factors such as order quantity, complexity, and material availability. However, Cablepoint is committed to providing competitive lead times without compromising quality. Please contact our team for a specific quote here.

Cablepoint implements rigorous quality control measures to ensure the durability of our moulded cables. This includes material testing, process monitoring, and finished product inspection. Our skilled technicians and advanced manufacturing processes guarantee the long-term performance of our products.

Yes, Cablepoint offers custom cable lengths and configurations to meet your specific needs. We work closely with you to understand your requirements and design a moulded cable solution that perfectly fits your application.

Contact us today to discuss your crimped wire requirements

Looking for a proactive manufacturing partner that delivers exceptional value? Cablepoint is your reliable choice. We’re committed to meeting both urgent and long-term requirements with precision and complete flexibility.

Our Production Capabilities

From simple wiring looms to complex harnesses, we can produce any required quantity. We also offer a refurbishment option on products, if required.

We produce a wide range of box build and control panels for a number of industries - from pharmaceutical to boiler manufacturers.

We have custom overmould and potting facilities on site. Depending on the cables required, the cost of any tooling can be amortised across your contract.

Our team is IPC trained, with experience producing a wide range of cable assemblies. From simple stripped, tinned, bootlaced and crimped wires to soldered wires and PCB connection.

We provide initial, pre-production cables to ensure complete accuracy, followed by full batch production. Customers may also use this facility for engineering prototypes and design ‘first-offs’.

We have two automated terminating machines with a tinning facility, enabling quality crimped wires to be produced economically and efficiently in large volumes.

Our clean room facility facilitates the production of high end F.O.D (Foreign Object Debris) sensitive specialist cables.