Precision Clean Room Cable Production

Clean Room Cable Assembly

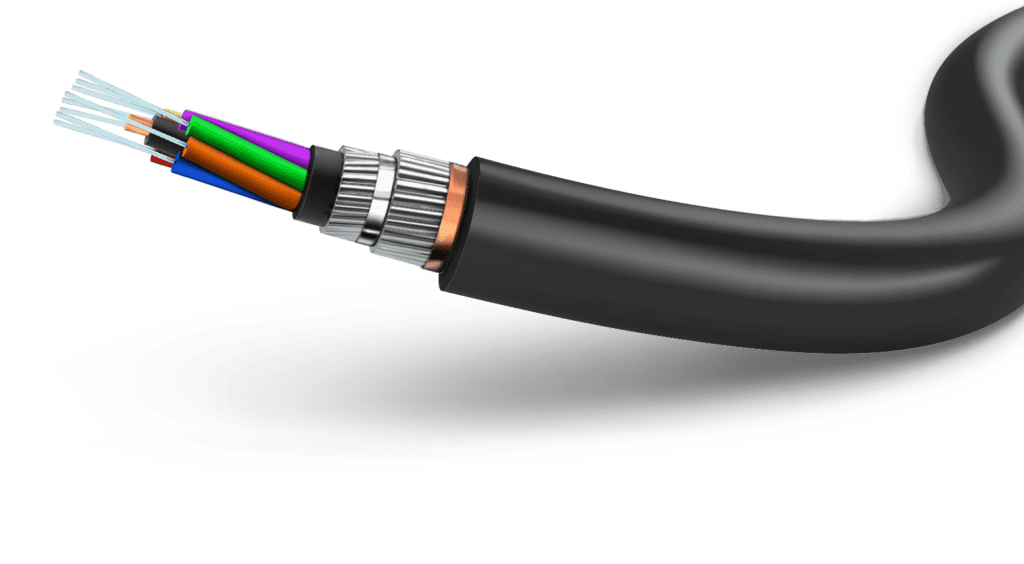

At Cablepoint, we recognise the importance of precision in every project. Our clean room facility enables the meticulous production of Foreign Object Debris (F.O.D) sensitive cables, ensuring that each cable assembly meets the highest standards. This controlled environment minimises contaminants, making it ideal for industries that demand absolute cleanliness and reliability.

Customised Clean Room Solutions for Specialist Applications

We understand that each cable assembly project has unique requirements, especially in F.O.D-sensitive environments. From delicate signal cables to robust power connections, our team can tailor solutions to fit your exact specifications. With advanced testing and quality control measures in place, we can deliver both small-scale prototypes and high-volume production with unparalleled consistency.

Clean Room Expertise

Our expertise extends across a range of industries, including aerospace, medical, and defence sectors. Every project undergoes strict quality control procedures in our clean room facility to ensure optimal performance and longevity. We are committed to meeting industry standards and delivering products that excel in demanding environments.

Discuss Your Cable Requirements with Our Experts

Contact us today to discuss your cable assembly requirements

Looking for reliable, sensitive cable assemblies? Our experienced team at Cablepoint is here to help. Whether you have specific requirements or need guidance on the best materials and configurations, we’re ready to support your next initiative. Contact us today to discuss how we can meet your clean room cable needs.

Our Production Capabilities

From simple wiring looms to complex harnesses, we can produce any required quantity. We also offer a refurbishment option on products, if required.

We produce a wide range of box build and control panels for a number of industries - from pharmaceutical to boiler manufacturers.

We have custom overmould and potting facilities on site. Depending on the cables required, the cost of any tooling can be amortised across your contract.

Our team is IPC trained, with experience producing a wide range of cable assemblies. From simple stripped, tinned, bootlaced and crimped wires to soldered wires and PCB connection.

We provide initial, pre-production cables to ensure complete accuracy, followed by full batch production. Customers may also use this facility for engineering prototypes and design ‘first-offs’.

We have two automated terminating machines with a tinning facility, enabling quality crimped wires to be produced economically and efficiently in large volumes.

Our clean room facility facilitates the production of high end F.O.D (Foreign Object Debris) sensitive specialist cables.