Choosing the right cable solution is critical when designing or...

Moulded and Potted Cable Assembly

Moulded Cable Manufacturing: Custom Cable Assemblies

At Cablepoint, we offer a comprehensive range of custom-moulded and potted cable assemblies, made to meet the most demanding requirements. Our moulded cables are renowned for their exceptional quality, durability, and resistance to environmental factors.

The Moulded Cable Difference: What is the purpose of moulding?

Moulded cables and pot end cables provide a superior level of protection and durability compared to traditional cable assemblies. The overmoulding process encapsulates the cable termination, creating a seamless and watertight seal.

This enhances the cable’s resistance to:

Abrasion: Protects against wear and tear

Chemicals: Resists corrosion and degradation

Moisture: Prevents water ingress and damage

Custom Moulded Cables: How Does Moulding and Potting Work?

- Material Selection: Choosing the right materials for optimal performance and durability.

- Mould Tooling: Developing precise mould tooling for consistent and high-quality production.

- Assembly: Precision assembly of cables and connectors.

- Overmoulding: We transition seamlessly to full-scale production once designs are finalised.

- Testing and Inspection: Rigorous quality control to ensure product excellence.

Industries Served for Cable Moulding and Potting:

- Pharmaceutical: Meeting the cleanliness and reliability standards of the pharmaceutical industry.

- Military: Delivering robust and durable cables for demanding defence applications.

- Electric Vehicle (EV): Supporting the transition to electric.

- Agricultural: Providing reliable and weather-resistant moulded cable for agricultural.

- Traffic Management: Contributing to efficient and safe transportation systems with specialised cables.

- Health and Beauty: Supplying cables for medical and beauty equipment.

We understand the unique challenges faced by each industry and can provide tailored solutions to meet specific requirements.

Looking for full-service cable assembly? See our full list of capabilities here.

Compliance

Exacting compliance, with quality at the heart of everything we do

Reliability

We've been manufacturing cable assemblies for our clients since 1991

Sustainability

Sustainability is at the heart of everything we do

Local Service, Global Delivery

From small projects for local SMEs, to global businesses

Why Choose Cablepoint for Your Moulded and Potted Cables?

Customisation

We create moulded cables to your exact specifications.

Expertise

Established for over 30 years, Cablepoint brings a wealth of industry knowledge to every project. Our experts have tackled diverse specifications across various sectors, including military, electric vehicle and agricultural to name just a few, ensuring that you benefit from our deep pool of experience, from our friendly team. Our longevity is a testament to our consistent delivery of high-quality solutions and our ability to adapt to changing industry needs.

Sustainability

We’re dedicated to reducing our carbon footprint. In recent years, we have been taking proactive steps to reduce our carbon footprint, reduce waste and become a more sustainable business. Read about our approach here.

Quality and Durability

We adhere to strict quality standards to ensure product reliability. Our moulded cables are built to withstand harsh environments.

Fast Turnaround

While proudly based in Hull in UK, our services extend worldwide. We have the capability to deliver our products across the globe, offering competitive lead times without compromising quality.

Common Questions About Moulded Cables

Moulded cables offer several advantages over traditional cable assemblies. They provide enhanced durability, protection against environmental factors (such as water, chemicals, and abrasion), and improved strain relief. The seamless integration of the cable and connector also eliminates potential points of failure.

The choice of material for moulded cable overmoulding depends on the specific application requirements. Common materials include:

- Thermoplastic elastomers (TPE): Offer flexibility, durability, and resistance to environmental factors.

- Thermoplastic polyurethane (TPU): Known for its toughness, abrasion resistance, and flexibility.

- Silicone: Provides excellent heat resistance, electrical insulation, and durability.

- Epoxy resins: Offer superior chemical resistance and mechanical properties.

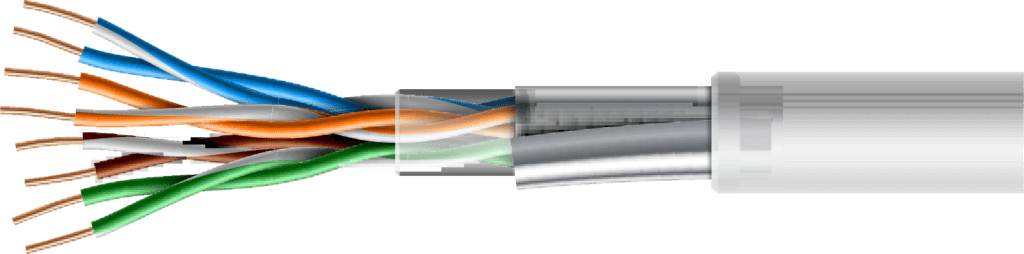

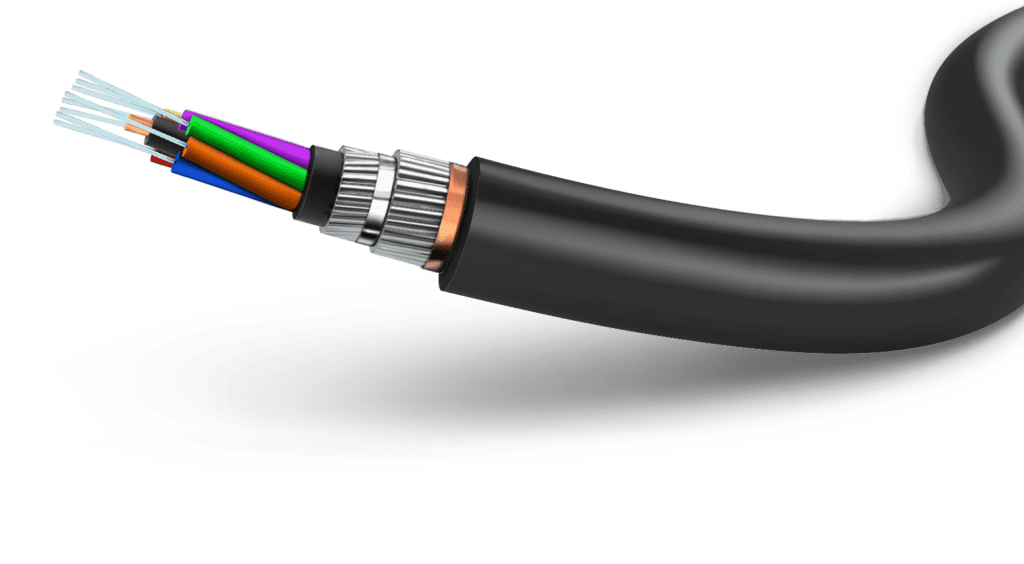

Yes, Cablepoint can mould different cable types to suit various applications. Whether you need power, data, or signal cables, we can create custom moulded cable assemblies.

The lead time for a moulded cable project varies depending on factors such as order quantity, complexity, and material availability. However, Cablepoint is committed to providing competitive lead times without compromising quality. Please contact our team for a specific quote here.

Cablepoint implements rigorous quality control measures to ensure the durability of our moulded cables. This includes material testing, process monitoring, and finished product inspection. Our skilled technicians and advanced manufacturing processes guarantee the long-term performance of our products.

Yes, Cablepoint offers custom cable lengths and configurations to meet your specific needs. We work closely with you to understand your requirements and design a moulded cable solution that perfectly fits your application.

Customer Testimonials

Get a Quote Today

Looking for a proactive manufacturing partner that delivers exceptional value? Cablepoint is your reliable choice. We’re committed to meeting both urgent and long-term requirements with precision and complete flexibility.

Our Production Capabilities

From simple wiring looms to complex harnesses, we can produce any required quantity. We also offer a refurbishment option on products, if required.

We produce a wide range of box build and control panels for a number of industries - from pharmaceutical to boiler manufacturers.

We have custom overmould and potting facilities on site. Depending on the cables required, the cost of any tooling can be amortised across your contract.

Our team is IPC trained, with experience producing a wide range of cable assemblies. From simple stripped, tinned, bootlaced and crimped wires to soldered wires and PCB connection.

We provide initial, pre-production cables to ensure complete accuracy, followed by full batch production. Customers may also use this facility for engineering prototypes and design ‘first-offs’.

We have two automated terminating machines with a tinning facility, enabling quality crimped wires to be produced economically and efficiently in large volumes.

Our clean room facility facilitates the production of high end F.O.D (Foreign Object Debris) sensitive specialist cables.